Connecting Warehouses: Why Structured Cabling is Critical for Logistics

In today’s fast-moving logistics industry, warehouses rely on advanced technology to manage inventory, track shipments, and streamline order fulfillment. However, without a strong and reliable network infrastructure, warehouses face challenges like poor signal strength, delayed inventory updates, and inefficient workflows.

Structured cabling plays a crucial role in supporting automation, real-time tracking, and seamless operations. By investing in the right cabling solutions, warehouses can improve efficiency, enhance security, and future-proof their operations. In this post, we explore the role of structured cabling in logistics and how it transforms warehouse management.

1. Challenges in Warehouse Connectivity

Many warehouses still operate with outdated or inadequate network infrastructure, leading to several operational inefficiencies:

Weak signal strength – Large warehouse spaces often experience network dead zones, affecting device connectivity.

Delayed inventory updates – Poor network reliability causes delays in barcode scanning and RFID tracking, leading to inaccurate stock records.

Inefficient workflows – Slower network speeds disrupt real-time data transmission, affecting warehouse automation systems.

Security vulnerabilities – Lack of structured cabling can lead to weak cybersecurity measures, risking data breaches and unauthorized access.

To address these challenges, structured cabling is essential for a reliable, high-performance network that supports modern logistics technology.

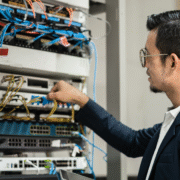

2. The Role of Structured Cabling in Warehouses

A well-planned structured cabling system supports seamless operations and automation in logistics by enabling:

A. Reliable IoT Device Connectivity

IoT sensors monitor inventory levels, temperature, and equipment status in real time.

Automated pick-and-pack systems rely on fast and stable data transfer.

Smart shelving and AI-driven logistics improve space utilization and stock control.

B. Faster and More Accurate RFID Tracking

RFID systems require high-speed data transfer to track shipments and inventory efficiently.

Structured cabling eliminates connectivity delays, ensuring accurate stock updates.

Improves order accuracy by reducing human errors in scanning and logging inventory.

C. Enhanced Automated Systems

Autonomous forklifts and robotic pickers depend on real-time network communication.

Cloud-based warehouse management systems (WMS) need uninterrupted data access.

Smart conveyor belts and automated sorting rely on consistent network speeds.

3. The Case for Fiber Optics in Warehouses

Fiber optic cabling offers significant advantages for modern warehouses:

High-speed data transfer – Fiber optics can handle large data loads with minimal latency.

Extended coverage – Supports strong connectivity even in large-scale facilities.

Scalability – Future-proofs warehouses for increasing automation and IoT adoption.

Enhanced security – Fiber optic cables are less susceptible to cyber threats and data interception.

By upgrading to fiber optic structured cabling, warehouses can achieve faster order fulfillment, better inventory control, and improved operational efficiency.

4. Case Study: How a Logistics Company Transformed Operations with Structured Cabling

A major logistics company struggling with network downtime, delayed shipments, and inaccurate inventory tracking upgraded to structured cabling. The results:

- 30% improvement in order fulfillment speed.

- Reduced stock discrepancies with real-time RFID tracking.

- Seamless communication between warehouse floors, offices, and cloud-based management systems.

- Eliminated network dead zones, improving automation efficiency.

This upgrade not only boosted productivity but also positioned the company for future warehouse technology advancements.

5. FAQs About Structured Cabling for Warehouses

Why do warehouses need structured cabling?

Structured cabling provides a reliable and scalable network, ensuring uninterrupted connectivity for inventory tracking, automation, and security systems.

What type of cabling is best for warehouses?

Fiber optic and Cat6A cabling are ideal, offering high-speed data transfer, extended coverage, and enhanced security.

How does structured cabling improve warehouse security?

By supporting IP-based security systems, structured cabling ensures real-time monitoring, access control, and cybersecurity protections.

Is structured cabling a long-term investment for warehouses?

Yes. A well-installed structured cabling system reduces downtime, enhances efficiency, and future-proofs warehouses for IoT, AI, and automation advancements.

Can structured cabling support warehouse expansions?

Absolutely. Structured cabling is modular and scalable, allowing easy upgrades as warehouse operations grow.

![]()

Conclusion: Optimize Your Warehouse Connectivity with Structured Cabling

Structured cabling is critical for modern logistics, ensuring seamless operations, real-time tracking, and automation. Investing in high-performance network infrastructure helps warehouses improve efficiency, security, and scalability.

Looking to upgrade your warehouse network? Contact us today for a free assessment of your cabling needs.

Leave a Reply

Want to join the discussion?Feel free to contribute!